Environment

CMM laser cutting is committed to respect and protect the environment by pursuing the continuous improvement of its methods and machinery, so as to attenuate the risks associated with the activities performed and the products/ services offered.

To achieve this goal, over the last six years, the company has made major investments that have led to the following results:

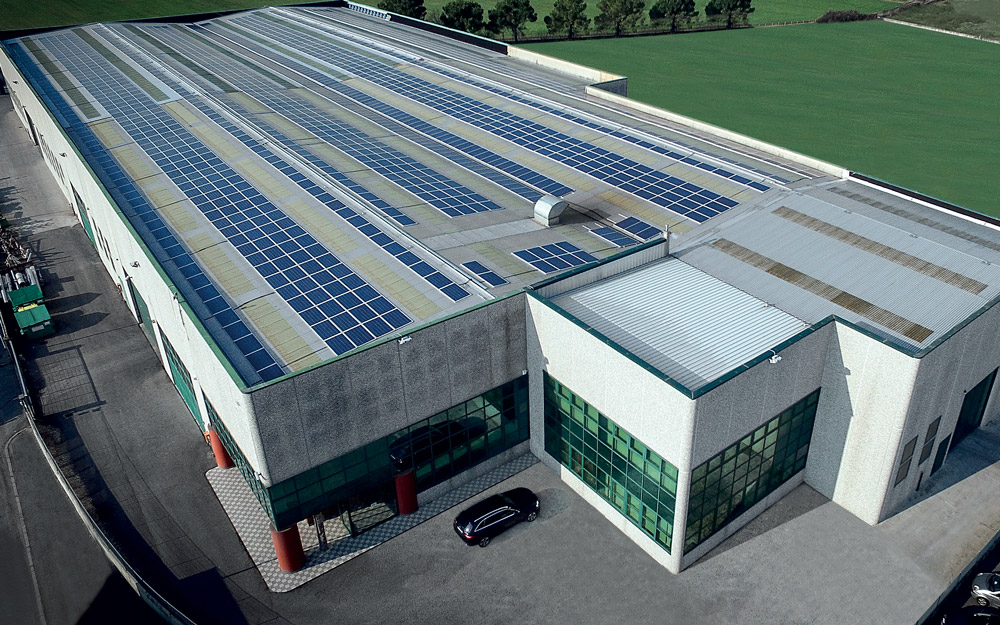

- Installation of photovoltaic panels, with a total power of 806 kW, most of which is used internally.

- Replacement of neon light fixtures with induction lamps

- Installation of two sheet metal cutting laser systems, one of them using fibre laser technology, with an appreciable reduction in power consumption.

- Installation of two tube cutting laser systems, one of them using fibre laser technology, also resulting in reduced energy consumption.

- In 2017, two bending machines and a punching press were installed within the framework of national technology upgrade plan Industry 4.0.

- The objective for 2018, to be achieved in collaboration with our system manufacturers, is to complete a Technology Revamping process involving the overhaul and restructuring of our production systems, with the aim to prolong their service life. The expected bene ts include improved performance, reduced energy consumption, and a reduced impact on the environment.

In keeping with the commitments undertaken, CMM laser always pays undivided attention to worker health and safety regulations, it continuously updates its methods in keeping with changes in the legislation, and trains and informs its employees on these matters, We are constantly striving to improve our production processes with innovative techniques and ever-safer machinery. As for waste management modalities, we promote salvaging and recycling as opposed to disposal.